Small caliber ammunition demands high material requirements on waterproofing, sealing, anticorrosive protection, the shelf life and bullet pull-out strength.

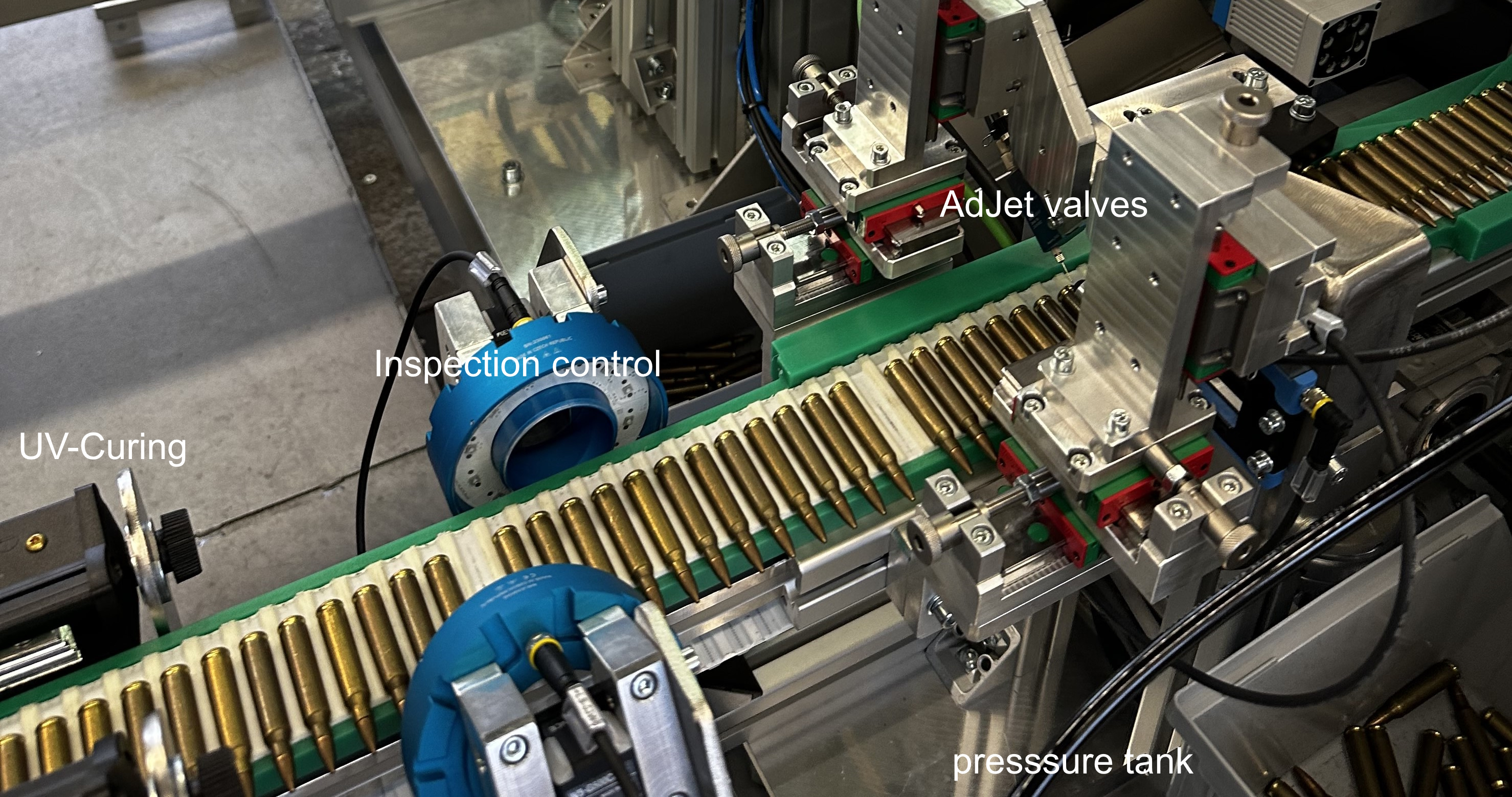

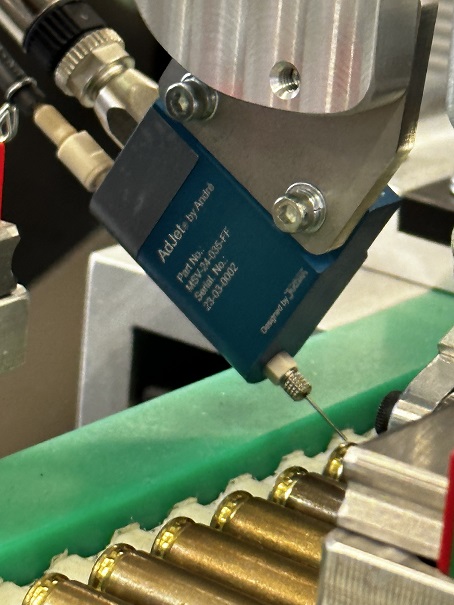

The range of products for the respective segment offers a wide variety of interior ammunition coatings, exterior ammunition varnishes, external sealants and the sealing technology.

We also develop and produce monolayer enomels, antifriction varnish, bituminous varnish, cartridge interior coatings according the German Bundeswehr TL, Nato and the US MIL-Spec specifications.

| Description | Characteristics | Viscosity | Temperature | Colour | Standard / approval |

|---|---|---|---|---|---|

| Interior coating | Interior of the ammunition, extremly resistant to propellant powder | 45 sec | air dry and baking varnish | black, grey, green | TL8010-0022 TL8010-0038 |

| Exterior coating | Exterior of the ammunition, antifriction varnish | 30 – 60 sec | baking enamel | colourless, green, grey | TL8010-0025 TL8010-0026 |

| Bitumen varnish | Bituminous varnish to seal the case mouth, solvent or waterbased | 40 sec | air dry | black | TL8010-0022 MIL-C-450B MIL-C-13783C |

| Primer groove varnish | Primer sealing | 100 sec | air dry | green, red, blue, black glazing, fluorescent as option | TL8010-0024 MIL-A-82484 |

| External sealant | Sealing the primer and the bullet for different calibers | 8 – 15 cP | UV light and anaerobic | red, green, blue, yellow, colourless, fluorescent |